Keywords:APIs, biocatalysis, (engineered) enzymes, high value molecules, microbial fermentation, recombinant microbial strains.

We develop bioprocesses using biocatalysts (enzymes or microorganisms) in single or multiple transformation steps.

These transformations take place at room (or close to it) temperatures and in some cases in water (instead to the

classical organic reactions, which need other solvents and much higher or lower temperatures), that minimizes

significantly the impact of our technology on the environment.

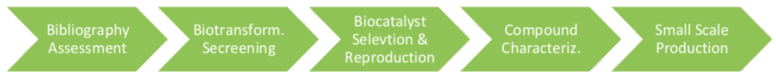

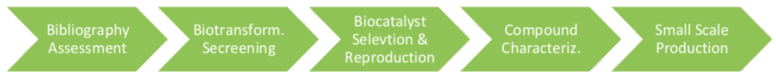

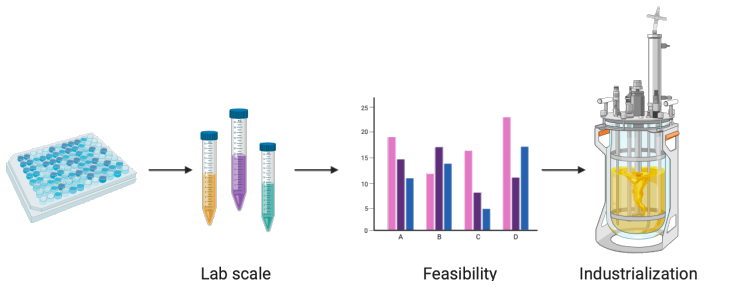

Our company follows a project management approach which comprises several development stages:

- Discovery stage:

- Bioprocess stage:

The information obtained from Bioprocess stage allows estimations of productivity,

costs and risks needed to confirm whether the process is feasible at industrial scale.

Each phase is neither planned nor quoted until the previous phase is not completed

and the results presented.

The customer decides the project continuation at each

phase depending on results and conclusions obtained so far.

We offer the following contract research services to customers:

- Technical Assessments and Consulting

We offer theoretical evaluations and consulting to verify the feasibility of substituting chemical synthetic processes by biotechnology.

Experimental work is also possible; the assessments include estimations of yields, engineering needs, costs, risks, regulatory aspects, etc., for doing this we have a worldwide network of contacts: suppliers of biocatalysts, manufacturers,

analytical services,

researcher, advisors, etc.

- Development of biotechnology processes

The substitution of processes based on synthetic organic chemistry

by biotechnology, can transform it to be more efficient, cost saving and less contaminant.

Another issue is that the bioprocess can be highly selective, and usually allows to reduce synthetic pathways [e.g.

protection/deprotection steps].

- Obtaining building blocks

Building blocks obtained by biotechnology can be used as alternative source of

reagents, starting materials and intermediates for chemical synthesis.

- Support in discovery of new chemical entities

Biocatalysts can be used to obtain new lead, lead optimization,

me-too and me-better compounds by modification of already available structures.

We have a powerful

network of contacts in biocatalysis and bioprocessing. Several partnership agreements have

been established.

Our most recent experience is based on the following processes:

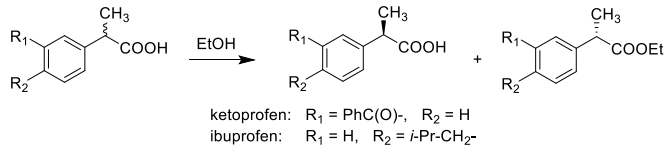

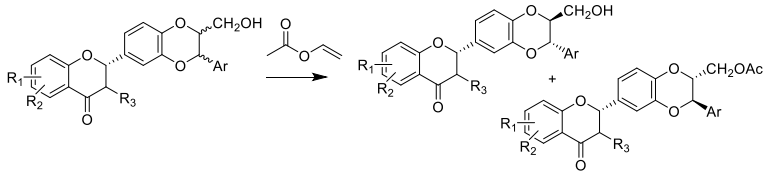

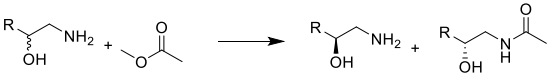

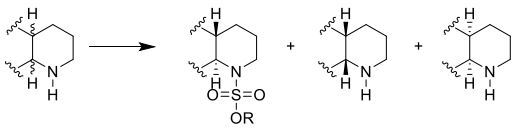

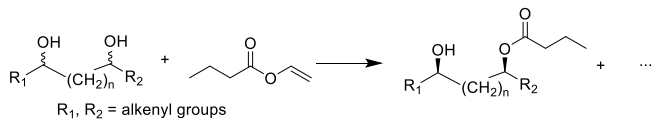

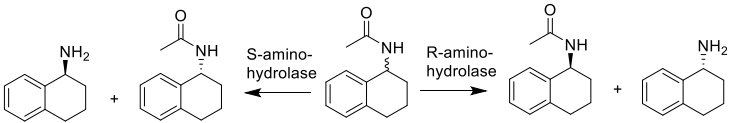

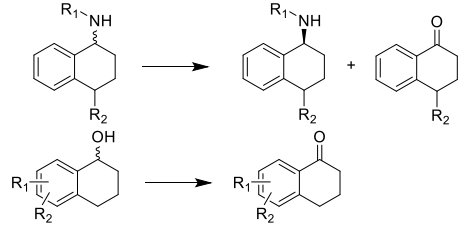

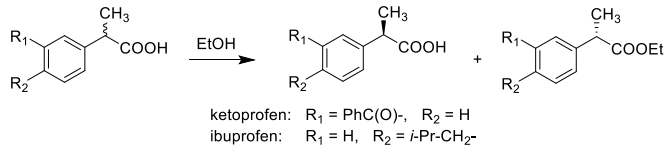

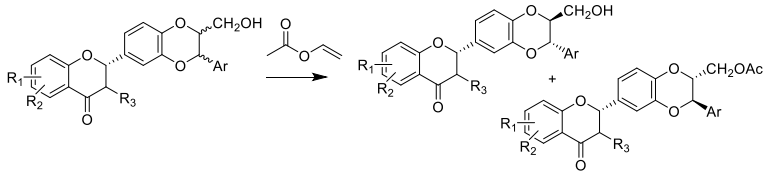

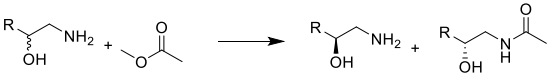

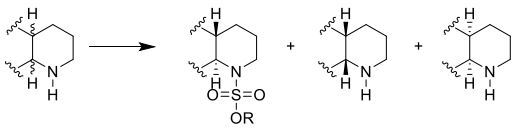

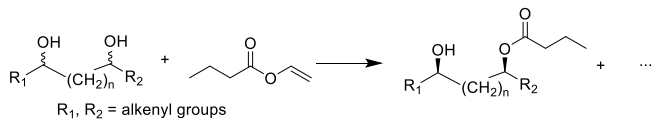

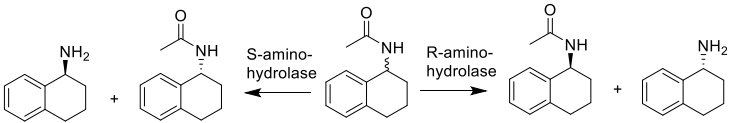

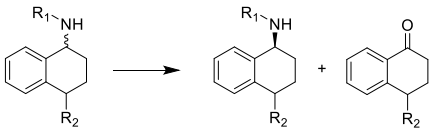

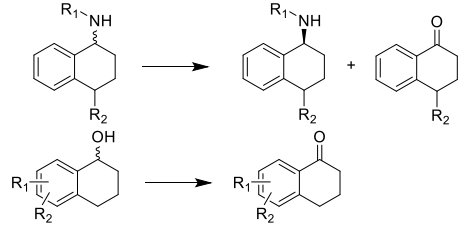

- Ressolution/ purification/ isolation of enantiomers of racemic mixtures using enzymes

Racemic resolutions are carried out by enantioselective acylation (through esterification, amidation,

transamidation or transesterification; or other reagents like sulphur derivatives) upon the enantiomer mixture,

using lipases as catalysts in organic media.

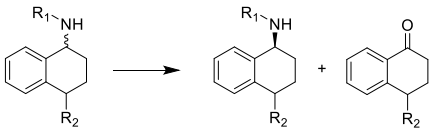

Other types of transformations can be also used for racemic resolution, such as oxidative deamination.

The only must for all these cases is that the enzyme used as catalyst has enantioselectivity for the substrates to

be transformed.

Some examples are:

- arylpropionic acids with anti-inflammatory activity

- flavolignan derivatives

- 1-amino-2-alcohol derivatives

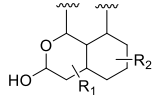

- piperidine / hydroquinoline derivatives

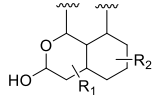

- alkenyldiol derivatives

- hydronaphthalene derivatives by de-acylation

- hydronaphthalene derivatives by oxidative de-amination

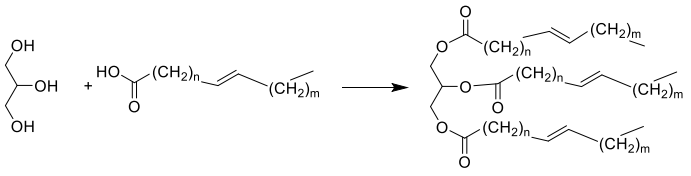

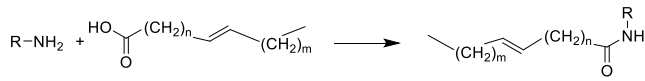

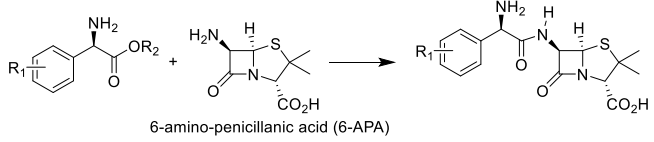

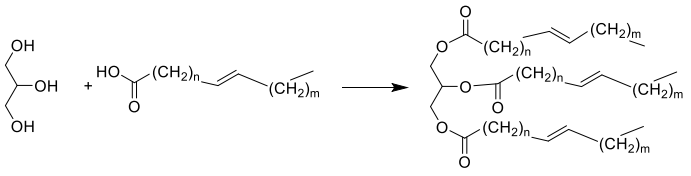

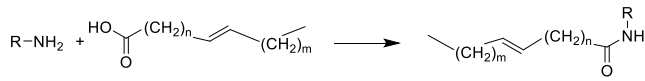

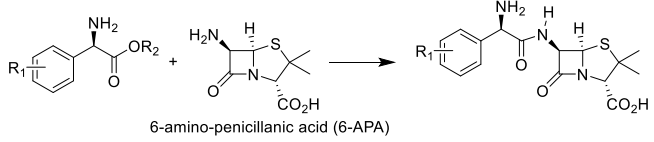

- Esterifications and amidations

Esterifications and amidations are widely used reactions carried out using lipases as catalysts in organic media.

These processes share the same basic technical concept as the racemic resolution, but the aim is not to separate

enantiomers, but to obtain an ester or an amide compound.

Some examples are:

- glycerol and fatty acids

- amidation of peptides with fatty acids

- penicillin derivatives

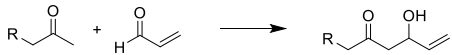

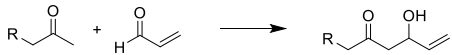

- Aldol reactions

Aldehyde and ketone compounds react through aldol reactions which make a new C-C bond to be formed

between the starting products. The process can be accelerated if enzymes with aldolase activity are used as

catalysts.

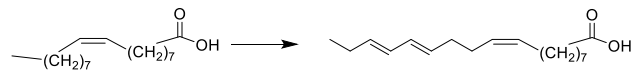

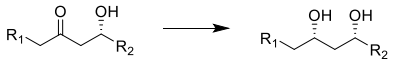

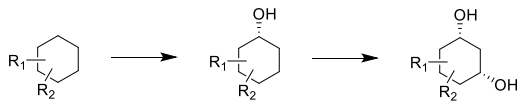

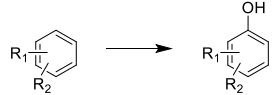

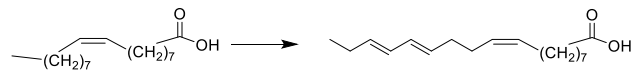

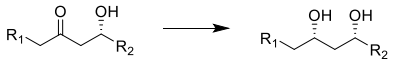

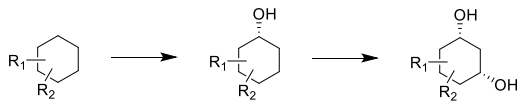

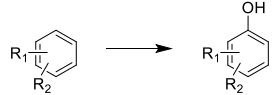

- Redox reactions

Several enzymes (desaturases, dehydrogenases, oxidoreductases) can be used as biocatalysts.

Some examples:

- hydronaphthalene derivatives

- vegetable oils dehydrogenation

- carbonyl reduction of hydroxyketones

- hydroxylation of alkane derivatives

- hydroxylation of aromatic rings

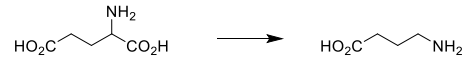

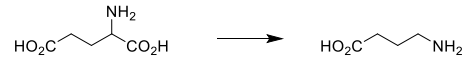

- Decarboxylations

Carboxylyases, also known as decarboxylases, are enzymes that add or remove a carboxyl group in several

compounds.

Example:

- γ-aminobutyric acid (GABA)

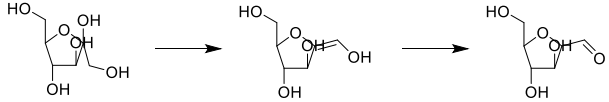

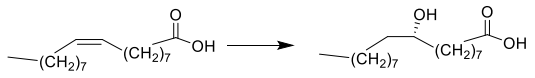

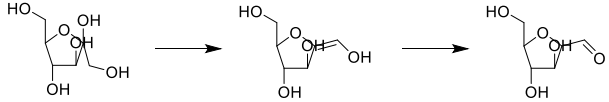

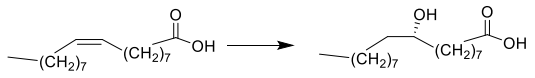

- Hydrations and dehydrations

The use of hydratases and dehydratases allows adding or removing a water molecule to a given structure. An

alkene group is formed after dehydration or the functional group to which hydration occurs.

Some examples:

- fructose dehydration

- hydration of unsaturated fatty acid derivatives

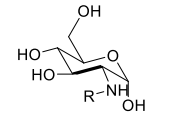

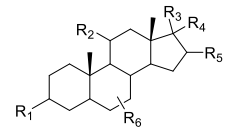

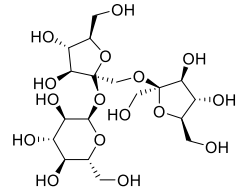

- Microbial fermentation processes

Biocatalytic transformations can be performed either with pure enzymes or using the enzymatic machinery of

microorganism as whole cells (bacteria, fungi, yeasts). Wild type and recombinant microorganisms can be used

for this purpose.

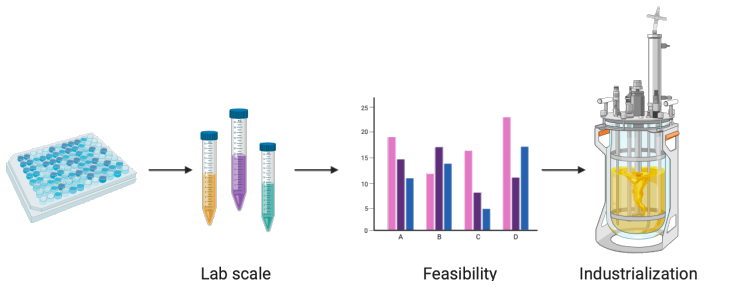

We have a wide experience in fermentation processes to manufacture high value products from lab to industrial

scale.

Some examples:

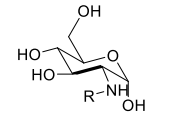

- aminosugar derivatives (are produced with a genetically modified microbial strain)

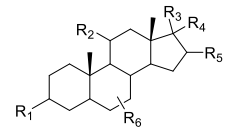

- steroid derivatives (are produced with the help of a genetically modified microbial strain from sugars as

galactose)

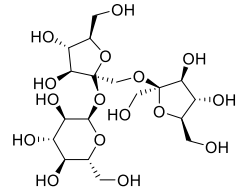

- prebiotics (by fructosyltransferase catalysis from sucrose)

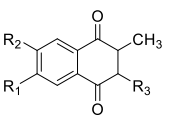

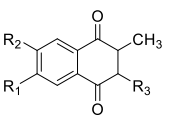

- vitamin K derivatives (by fermentation using a recombinant Escherichia coli strain that expresses a -

oxidoreductase)

- sesquiterpenoid hydrolactone derivatives (by fermentation with a genetically modified Saccharomyces strain)

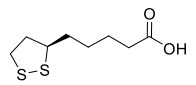

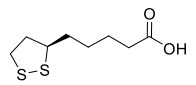

- α-lipoic acid (by fermentation with a recombinant strain which expresses an octanoyl- transferase from

Escherichia coli)

Please

contact us to request more details!